Features / Options

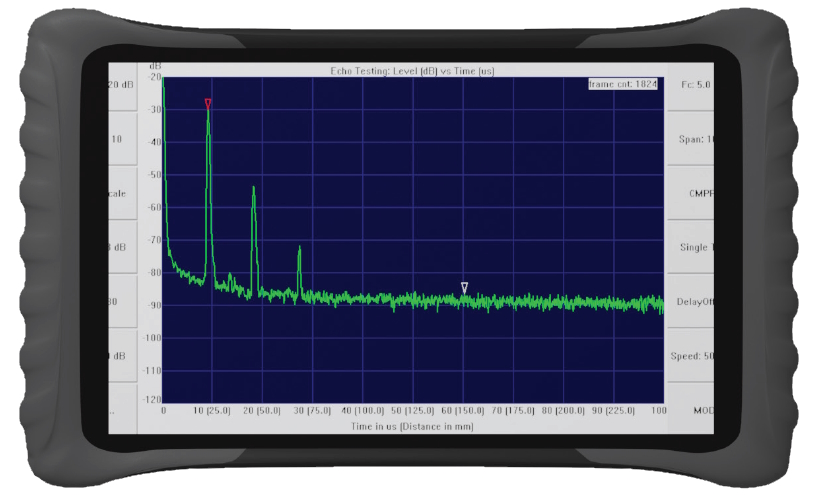

The UDLV-NDT 8801 is the world’s first low-voltage, deep penetrating industrial ultrasound NDT instrument using sophisticated, continuous, full duplex, pulse compression technology. Our mere 3V signal overtakes a 300V pulser unit. Our TOF (Time of Flight) measurement stability goes down to sub-nano-seconds

Revolutionary

- Truly unique ultrasound NDT (Non-Destructive-Testing) and Flow meter measuring device based on low-voltage pulse compression method.

- First of its kind that uses optimal full-duplex continuous long pulse compression method that achieves deepest penetration using only a few volts, instead of hundreds of voltages used by all incumbent pulser instruments

- The time and frequency domain optimized complex low voltage signal keeps the transducers and test subjects operating in ideal linear range, hence a user gets the best SNR: low noise floor, high resolution and sensitivity and negligible time-zero blind zone, all unattainable by the existing pulser instruments.